Decking Buying Guide

Senior Home & Tech Editor

Over the past few years, big changes have been underway in the decking world. Wood has historically been the material of choice for many homeowners, primarily due to its relatively low cost. However, composite materials have been decreasing in price, narrowing the gap with higher-grade wood decking.

Alternative materials are appealing for several reasons. Synthetic plank decking, for instance, offers an attractive appearance, with less upkeep than wood. Composites, which blend ground-up wood and plastic, also require minimal maintenance while simulating the look of natural wood and offering numerous color options.

Building or updating a deck can boost the value of your home. Use this buying guide to consider smart options that fit your budget and help create a space that’s relaxing, attractive, durable, and easy to care for. CR members with digital access can see our decking ratings.

Repair or Replace: Is It Time for a New Deck?

If your decking has cracks, looks dirty, or suffers from mildew, it’s time to decide whether to refinish it or replace it entirely.

Signs of an unsafe deck may not be immediately apparent, so safety checks are crucial when deciding whether to repair or replace it. Also, if your deck was built before 2004, there’s a good chance it’s made of lumber treated with chromated copper arsenate. Regular refinishing helps to seal in the toxic arsenic that CCA decking contains. However, if the finish is flaking or worn off in spots, we recommend hiring a professional who’s equipped to safely remove the old finish, dust, and debris, then refinish it. Here are some other considerations to keep in mind.

Weigh Costs

When pricing materials for a new or rebuilt deck, be sure to factor in the costs of railings, stairs, and the supporting structure, as well as the planks underfoot. If you’re hiring a pro, be aware that the cost of labor—either to build a new deck or to replace worn planking on an existing structure—can easily exceed the cost of the materials.

Complement Your Home’s Design

The width of the decking, its color and finish, and the shape of the railing are important design elements. A ranch, raised ranch, or contemporary house style can work well with many deck designs. It’s more challenging to make a deck work with an older home style, such as Tudor, colonial, or 1920s bungalow. Many manufacturers of synthetic decking offer a variety of railings, such as provincial- or Mission-style, that can help the deck fit with the rest of the house.

Sidestep Missteps

Deck screws tend to remain in place longer than nails. Ceramic-coated screws come in several colors, which helps them blend in.

To avoid splitting wood planks, drill pilot holes if you’re using nails and countersink screws. If you’re using composite materials, predrill screw holes. Choose zinc-coated or other corrosion-resistant fasteners, and use the right fasteners for composites. Also consider hidden fasteners or systems that hide the attachments. Most composite decking manufacturers also sell plastic plugs—designed to conceal holes from fasteners—that are color-matched to different decking lines.

Before staining, pressure-wash the old surface or brush it with a cleaning solution. If any mold or mildew remains, remove it using a solution of 1 part bleach and 3 parts water. When staining, use as many coats as the manufacturer recommends, and ensure the temperature outside is at least 50° F from the time the stain is applied until it dries completely.

Decking Types

Although wood is the most popular type of decking, other materials are gaining popularity among homeowners. Here are four types of decking material to consider.

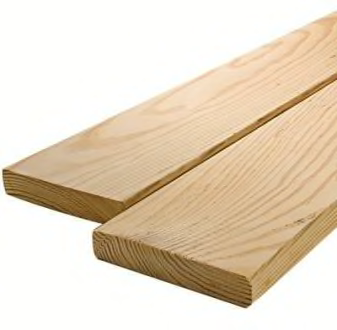

Wood Decking

Pros: Authenticity. Most is pressure-treated pine, but more expensive options include cedar, redwood, and tropical hardwoods.

Cons: Wood tends to change color, crack, and stain if it isn’t refinished, and boards may need to be replaced more frequently. Hardwoods and exotic choices can be expensive.

Price: About $200 to $1,100 or more per 100 square feet.

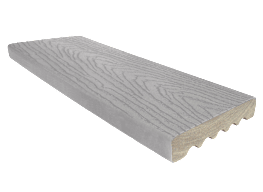

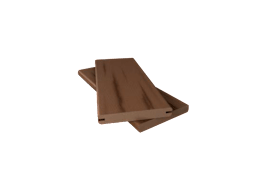

Composite Decking

Pros: It has the appearance of wood without the need for staining. It’s made of plastic and wood fiber, and sometimes can be stained to change its color. Most of these materials now come with some or all sides encased in plastic to prevent mildew growth.

Cons: Some materials offer far less resistance to slips, stains, and mildew than others. Most choices are heavier and more expensive than pressure-treated pine.

Price: About $300 to $700 per 100 square feet.

Plastic Decking

Pros: Best for resisting the elements without staining. Choices include PVC and polyethylene. It’s also lightweight.

Cons: Some products can look inexpensive, some are slippery, and all sagged more than wood in CR’s testing.

Price: About $525 to $1,200 per 100 square feet.

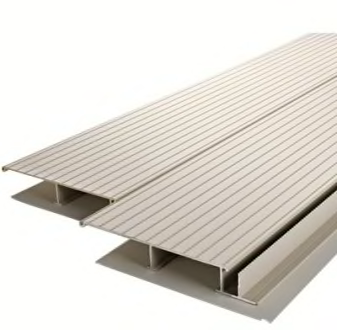

Aluminum Decking

Pros: Toughness, rigidity, and slip resistance. Aluminum decking’s baked-on or anodized finish is expected to last a long time, and CR’s testing confirms that its textured surface provides added traction. Sections sometimes interlock so that rain won’t drip through.

Cons: It’s expensive, and no one would mistake it for wood.

Price: More than $500 per 100 square feet.

Deck-Wise Features

We expose the boards we test to harsh weather for three years at test sites in hot and humid Florida and in hot and dry Arizona. Each year, we have the boards sent back to our labs in Yonkers, N.Y., to test them for a variety of attributes, including resistance to flexing, slipping, spills, and surface damage from dents and wear. Our exposure scores reflect how each model compares with the others in our tests.

CR members with digital access can see our decking ratings. Our tests have found that some composite decking products don’t make the grade for rigidity, and some tonier wood products outperform most composites.

Here are some more decking tips.

Wood Alternatives Are Generally Better at Resisting Sun and Spills

Most of the composite, plastic, and aluminum decking we test keeps its original color better than unfinished wood. Many also fend off mustard, wine, and other stains.

Wood Is Stiffer and Surer

Wood resists slips best in our friction tests. It also resists bending and sagging. A few plastics and composites come close in those tests, but several of them flex or sag noticeably.

Wood Alternatives Offer a Range of Design Options

Synthetic products are available in multiple colors, including white, gray, and various shades of brown. Surface textures include smooth (like plastic lawn furniture, in some cases), subtle wood grain, ridges, and some distinctively non-woodlike patterns. Some composite planks are flexible enough to be curved into patterns or shapes that would be expensive to duplicate in solid wood.

New Fasteners Improve Looks and Ease Installation

TrapEase is one brand that offers special-purpose screws intended for use with plastic and composite decking. They have coarse threads at the tip to bite into the deck’s supporting joist and finer threads toward the head to stop the decking material from bulging out.

Invisible fasteners suitable for wood or plastics come in three types: metal clips with sharp prongs that dig into the deck planks and the joist, elliptical wafers that fit into a slot cut into the sides of the planks and are held with a screw driven into the joist, and strips that fasten to the joist and underside of the plank. When all the planks are in place, the fasteners are not visible.

Snap-in-place fasteners are easy to install but unique to specific brands. One brand of aluminum decking we tested snaps together, much like tongue-and-groove flooring does. A vinyl decking product we reviewed snaps in place over metal clips screwed onto the joists.

Decking Brands and Materials

We test manufactured decking made by specific brands, as well as types of wood that are generally unbranded but reflect the materials you’ll find at home centers and building material suppliers.

Azek is a manufacturer of composite decking owned by CPG products, the same company that owns TimberTech. Azek products are available at Home Depot, Lowe’s, and other building material suppliers. Entry-level Azek products start around $4 per linear foot.

Cedar is a softwood that naturally resists damage from moisture. For years, it was the material of choice for outdoor porches. It requires periodic sealing and staining to resist wear from the elements. It can be purchased at home centers and lumberyards.

CertainTeed is a large manufacturer of vinyl home products, including siding and decking. It’s sold primarily at building supply stores.

ChoiceDek is a manufacturer of inexpensive composite decking available exclusively at Lowe’s stores. Prices start around $1.80 per linear foot.

Fiberon is a large manufacturer of composite decking. Its products are sold at Home Depot, Lowe’s, and building material suppliers.

Ipe is a beautiful hardwood traditionally harvested in South America. It’s naturally water- and warp-resistant, and its strength makes it resistant to dings, nicks, and splits. Because it was traditionally harvested in the Brazilian rainforest, it’s important to seek out environmentally sustainable options. Look for certifications from organizations like the Forestry Stewardship Council, which indicate that the decking was sustainably sourced.

LockDry is one of the largest manufacturers of aluminum decking. Its products have the distinct advantage of gapless installation, meaning there are no gaps between boards, creating a watertight and seamless finish. When used as a second-story decking material, the area below is kept dry. Its products are generally available to order from qualified installers and are not sold in most stores.

Pressure-treated southern yellow pine is the most popular decking material in the U.S. That’s largely because it was the least expensive option, historically. The wood is treated in a liquid chemical bath, resulting in vastly improved resistance to warping and rotting. Treated pine is 11 times more weather-resistant than regular stained pine. It’s widely available at home centers and building supply stores.

Redwood is a softwood grown primarily in the western U.S. Like cedar, it’s naturally weather-resistant, but you’ll pay a premium over pressure-treated pine. It’s available at building suppliers and lumberyards.

TimberTech is a large manufacturer of composite decking. Its products are sold at Home Depot, Lowe’s, and building suppliers. It offers multiple lines that start around $3.50 per linear foot, with some costing more than $6 per linear foot.

Trex is one of the largest and best-known manufacturers of composite decking. Its products are sold at home centers, including Home Depot and Lowe’s, as well as at building suppliers. It offers multiple product lines, with some starting at around $2 per linear foot and climbing to $6 or more per linear foot.

Veranda is a composite decking brand exclusive to Home Depot. Prices start around $1.50 per linear foot.